Thank you for the pictures Bill.

If you have a Google email account, you can use picasa (http://picasa.google.com/). It's a great photo sharing service that will let you serve full size images.

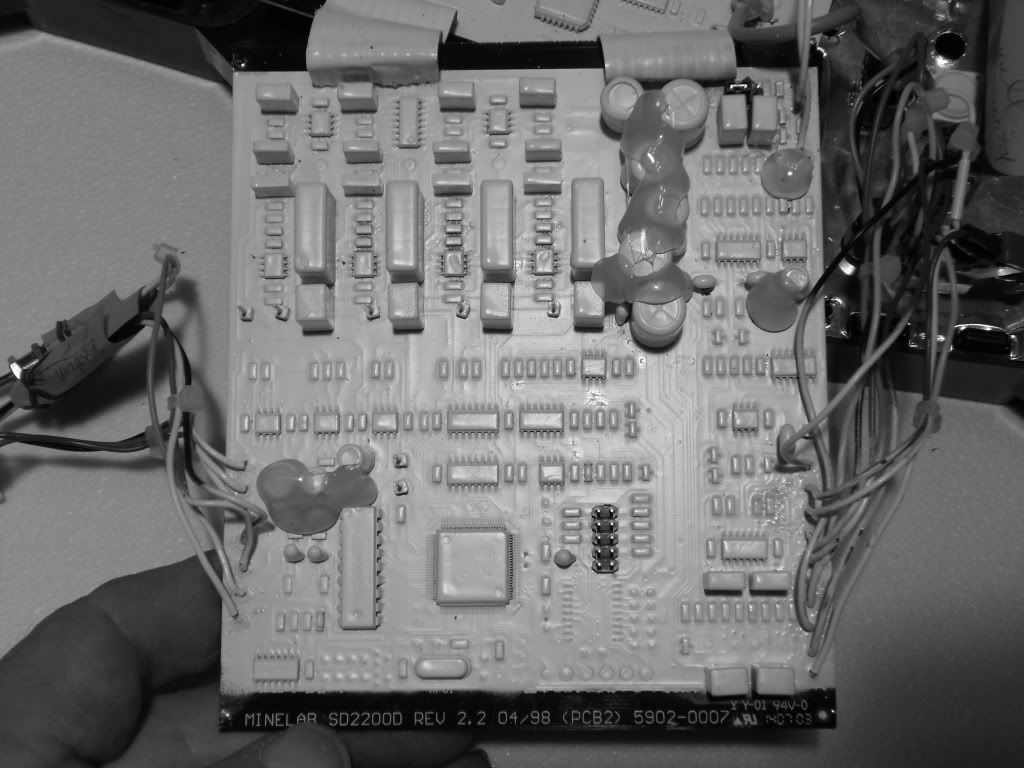

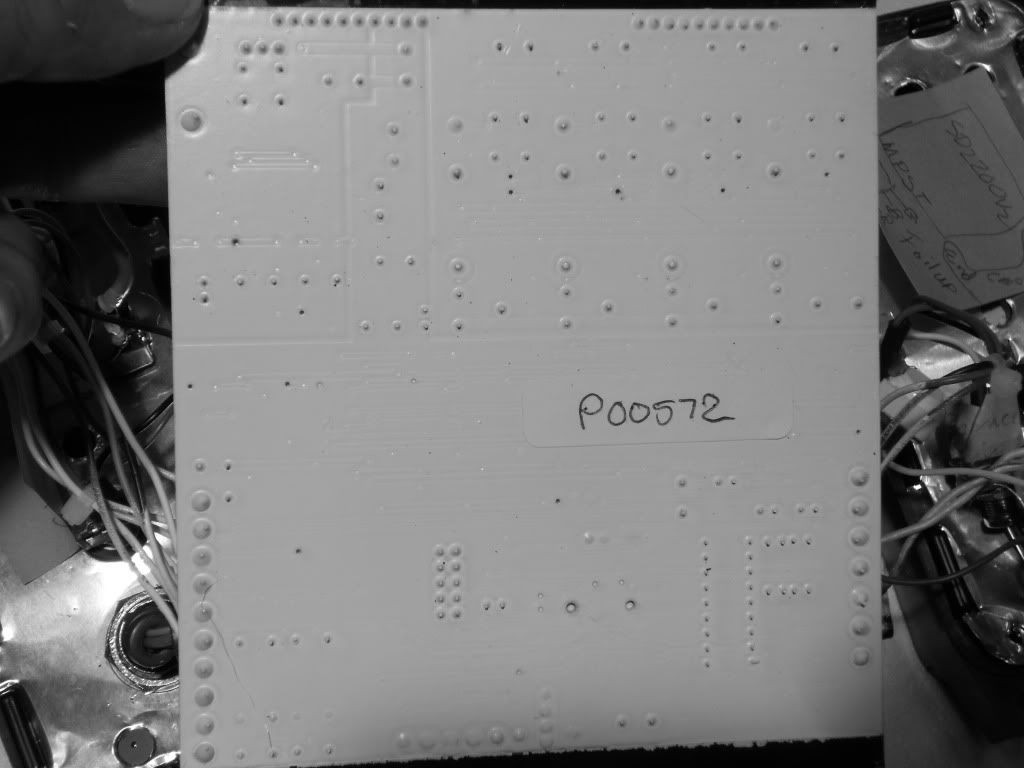

You can also email me the pics at my email, and I will gladly host them from my picasa account. I'm looking forward to seeing them blown up. Currently, the ones posted are a bit too small. It's hard to see any details.

If you have a Google email account, you can use picasa (http://picasa.google.com/). It's a great photo sharing service that will let you serve full size images.

You can also email me the pics at my email, and I will gladly host them from my picasa account. I'm looking forward to seeing them blown up. Currently, the ones posted are a bit too small. It's hard to see any details.

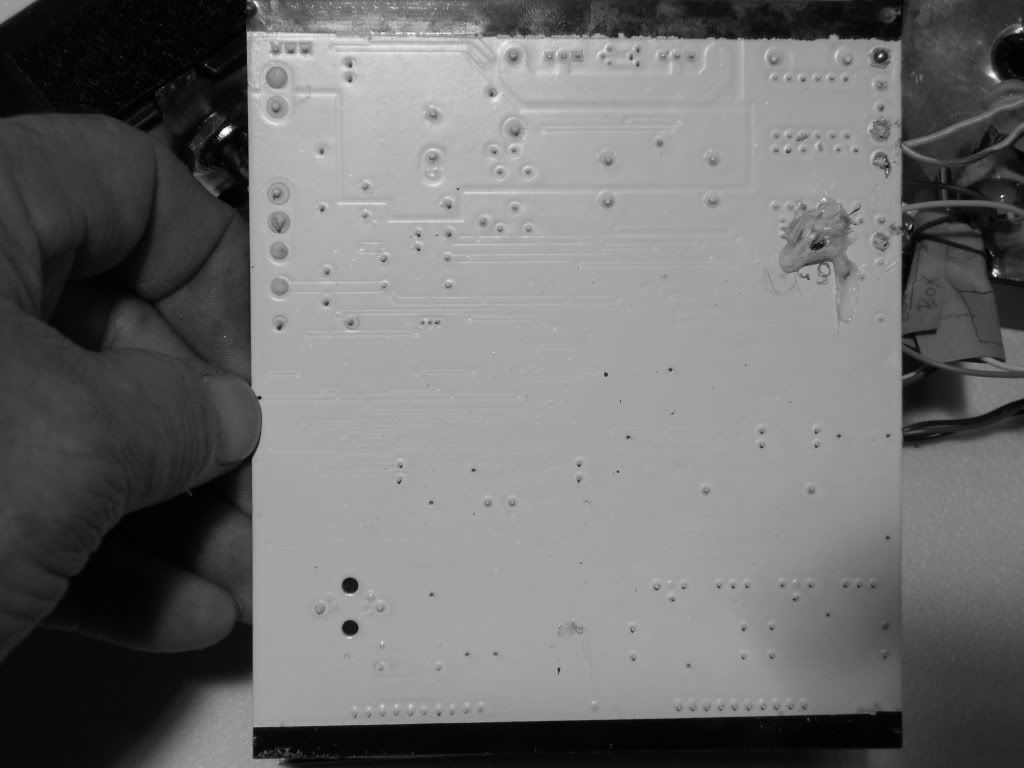

When finished, just clean up with more contact cleaner and dry. You will need to coat the boards with plasticoat or some other protective spray to keep the moisture out.

When finished, just clean up with more contact cleaner and dry. You will need to coat the boards with plasticoat or some other protective spray to keep the moisture out.

.

.

Comment